How to Conduct a Boiler Safety Audit in 7 Steps

Maintaining reliable boiler systems is essential for any facility that depends on consistent heating and hot water services. A systematic boiler safety audit helps you identify potential problems before they turn into costly emergencies that could disrupt your daily operations. Whether you need comprehensive boiler maintenance services to keep your systems running efficiently or emergency repair solutions when unexpected issues arise, understanding proper inspection procedures ensures your facility stays operational year-round. Regular safety audits not only protect your equipment investment but also help you avoid those expensive emergency calls that can really impact your budget.

Key Takeaways

- Documentation Requirements: Detailed inspection records support compliance and track equipment performance over time

- Safety Protocol Priority: Always follow lockout/tagout procedures and ensure proper ventilation before starting work

- Professional Assessment Value: Annual boiler inspections by certified technicians catch issues routine checks miss

- Preventive Cost Benefits: Regular audit schedules reduce emergency repair costs and minimize system downtime

- Component-Specific Focus: Different boiler components require specialized inspection techniques and safety considerations

- Compliance Tracking:

Organized inspection logs ensure adherence to local and federal safety regulations

Step 1: Pre-Audit Preparation and Safety Setup

Before you dive into any boiler inspection, you'll want to get your ducks in a row with proper safety protocols and gather all the documentation you'll need. Take some time to review your previous inspection reports, maintenance records, and manufacturer specifications. This homework helps you understand your system's personality and any quirky issues it might have. Make sure everyone on your team understands lockout/tagout procedures and has the right personal protective equipment.

Here's what should be on your comprehensive checklist:

- System shutdown procedures and how long you need to let things cool down

- Double-checking that all your testing equipment is properly calibrated

- Having emergency contact information for certified boiler technician support ready to go

- Setting up documentation templates so you can record findings systematically

- Establishing safety barriers around work areas to keep everyone safe

- Creating communication protocols so building occupants know what's happening

Smart facility managers benefit from this thorough preparation since unexpected system failures can really impact daily operations. Try to schedule your inspections during quieter periods when possible, and always have backup heating plans ready for those extended maintenance windows. Don't forget to consider seasonal factors that might affect both your inspection procedures and your facility's heating demands.

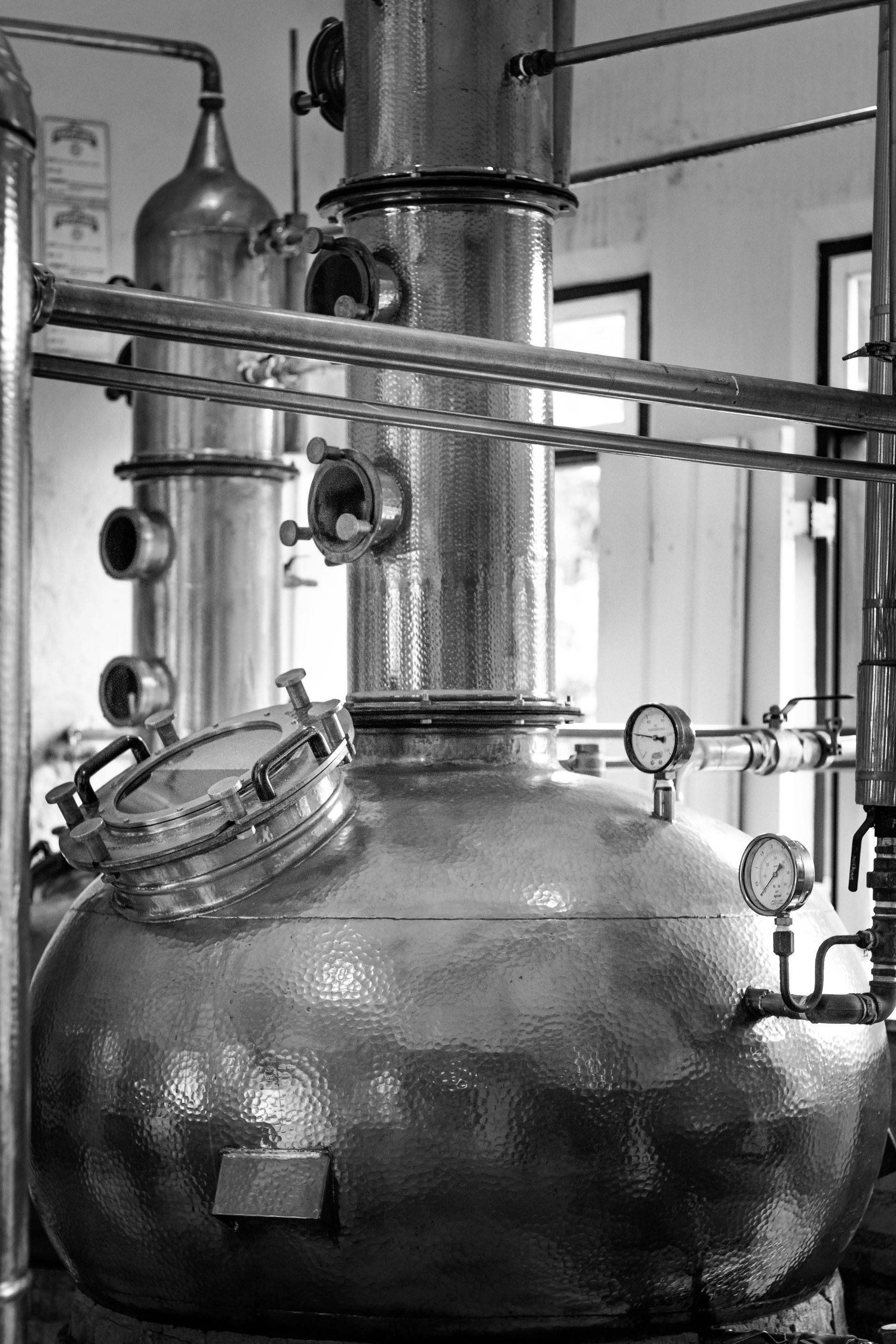

Step 2: Visual Inspection of External Components

Now comes the detective work: start your audit with a careful visual examination of all the external components you can access. You're looking for signs of corrosion, leaks, unusual wear patterns, or damage to insulation materials. Pay special attention to pipe connections, valve assemblies, and pressure relief systems that might be showing stress or deterioration.

Make sure you document everything you see with photographs and detailed notes about:

- Rust formation patterns or accelerated corrosion in specific areas

- Insulation damage that could be a red flag for temperature irregularities

- Pipe support integrity and proper alignment throughout the system

- Control panel condition and whether all gauges are easy to read

- Any unusual staining or discoloration on surfaces near connections

- Steam or water vapor emissions coming from joints or fittings

- Electrical connection security and wire insulation condition

Many facilities with continuous boiler operation find this visual inspection step especially important for catching those early warning signs before they become bigger problems. Regular monitoring really does help prevent small issues from snowballing into major system failures that could interrupt critical operations. When you're doing this systematic documentation, you're creating valuable baseline information that helps you track how components are aging over time.

Step 3: Pressure and Safety System Testing

This is where things get a bit more technical, but it's absolutely crucial. You'll need to test all pressure-related safety systems according to manufacturer specifications and regulatory requirements. This includes pressure relief valves, safety shutoffs, and all those automatic controls that protect against dangerous operating conditions. Make sure you're using calibrated testing equipment and following established procedures for each component type. Professional pressure testing requires a solid understanding of system operating parameters and safety margins.

Here's your Critical Safety System Checks reference:

| Component | Test Method | Acceptable Range | Action Required |

|---|---|---|---|

| Pressure Relief Valve | Manual lift test | Opens at set pressure ±3% | Replace if outside range |

| Low Water Cutoff | Water level simulation | Trips before unsafe level | Repair or replace |

| Pressure Controls | Pressure variation test | Within manufacturer specs | Calibrate or replace |

| Temperature Controls | Temperature cycling | Accurate within ±5°F | Adjust or replace |

Your annual boiler inspections absolutely must verify that these safety systems work correctly under various operating conditions. If any component fails testing, it needs immediate attention from qualified professionals before you put the system back into service, no exceptions. Your testing procedures should include verification of alarm systems, automatic shutdown sequences, and emergency response protocols that protect both personnel and equipment when things go sideways.

Make sure you document baseline performance parameters for all safety systems so you can establish trends and identify gradual deterioration that might compromise protection capabilities down the road. Regular testing also keeps you compliant with insurance requirements and regulatory standards that specify minimum safety system performance criteria. Consider how seasonal variations in system demand might affect safety system performance, as components that are calibrated for heavy winter heating loads might respond differently during periods of reduced operation.

Step 4: Water Quality and Treatment Analysis

Water quality might not be the most exciting topic, but it's absolutely critical for your boiler's health and longevity. Poor water chemistry is like feeding your boiler junk food: it accelerates corrosion, reduces heat transfer efficiency, and can lead to dangerous pressure buildups. You'll need to collect samples from multiple points in your system and test for key indicators including pH levels, dissolved oxygen, and chemical treatment effectiveness.

Water quality issues often show up differently depending on what type of facility you're running and how you use your system. Facilities with consistent hot water demands might experience different scaling patterns compared to those with more intermittent use. Regular monitoring helps you establish baseline parameters and identify trends before they cause expensive equipment damage.

Water treatment becomes especially critical for facilities that simply cannot tolerate service interruptions. Your preventive boiler maintenance should include maintaining optimal water chemistry to prevent scale formation, corrosion, and biological growth that can really compromise system reliability. Keep an eye on your chemical feed system operation to ensure consistent treatment delivery throughout all operating conditions.

Step 5: Combustion System and Efficiency Assessment

Now we're getting into the heart of your boiler's performance: combustion efficiency. This involves systematically analyzing fuel consumption, exhaust gas composition, and flame characteristics to make sure everything is running as efficiently as possible. Modern boiler systems should operate within specific efficiency ranges, and when you see deviations, they're often telling you that maintenance is needed or components are wearing out.

Combustion testing requires specialized knowledge and equipment that many facilities prefer to outsource to certified boiler technician services, and that's perfectly fine. Professional assessment ensures you get accurate readings and proper interpretation of results, especially when you're dealing with complex control systems or multiple boiler configurations.

Efficiency problems hit you right where it hurts: in your operating costs and environmental compliance. Facilities operating on tight budgets can see significant savings over time by maintaining optimal combustion performance through regular monitoring. Make sure you document combustion performance trends to identify gradual efficiency degradation that might indicate maintenance needs.

Step 6: Control System and Automation Review

Modern boiler systems rely heavily on electronic controls, and these smart systems need a different inspection approach compared to mechanical components. You'll want to verify that sensors are providing accurate readings, control logic is functioning properly, and alarm systems activate under the right conditions.

Take time to test sequence controls that manage startup, shutdown, and emergency procedures. These systems are your first line of defense against unsafe operating conditions, and they protect your equipment from damage when things don't go according to plan. Document any error codes, alarm history, or unusual behavior patterns that might indicate developing problems.

For many facilities that operate around the clock, reliable automation is essential for maintaining consistent environmental conditions. Regular control system maintenance prevents those unexpected failures that could compromise operational continuity or safety protocols. Consider what backup control capabilities you have and make sure manual override procedures are in place for emergencies.

Step 7: Documentation and Follow-Up Planning

This final step might not be the most exciting, but it's absolutely crucial for long-term success. You need to complete comprehensive documentation of all your inspection findings, including photographs, test results, and recommended actions. Organize everything in a format that supports regulatory compliance requirements and helps facility managers make smart maintenance decisions.

Develop a follow-up schedule that tackles immediate safety concerns while planning for routine maintenance activities. Coordinate with boiler maintenance services to ensure qualified technicians handle complex repairs or system modifications. Create monitoring protocols that track system performance between formal inspections so you can catch issues early.

Effective documentation supports insurance requirements, regulatory compliance, and budget planning for facility improvements. All facilities benefit from detailed records that demonstrate proactive maintenance practices and commitment to safety standards. Consider investing in digital documentation systems that make it easy to access historical inspection data.

Frequently Asked Questions

How often should facilities schedule comprehensive boiler inspections?

Most facilities do well with annual boiler inspections conducted by certified professionals, though facilities with heavy use might need more frequent check-ups. Your local regulations and insurance requirements often spell out minimum inspection frequencies that you'll need to follow.

What qualifications should inspectors have for boiler safety audits?

Your inspectors should hold appropriate certifications for the specific boiler types you're working with and stay current with safety codes and regulations. Many facilities find it easier to work with certified boiler technician services that provide properly trained and licensed personnel.

Can facility maintenance staff conduct boiler inspections independently?

While your staff can definitely handle routine visual checks and basic maintenance tasks, comprehensive safety audits require specialized training and testing equipment. Professional inspection services ensure thorough assessment and regulatory compliance for complex systems.

What immediate actions should facilities take when inspections reveal safety concerns?

Any safety-related issues that pop up during boiler inspections need immediate attention. This often means shutting down the system until repairs are completed. Contact qualified boiler maintenance services right away to address urgent problems and prevent potential hazards.

How do weather conditions affect boiler inspection scheduling?

Extreme weather can definitely impact both your inspection procedures and your facility's heating demands, making timing really important for service continuity. Try to plan inspections during moderate weather periods when possible, and always have backup heating arrangements ready.

Final Thoughts

Conducting thorough boiler safety audits really does protect your facility operations, ensure regulatory compliance, and prevent those costly emergency repairs through smart, proactive maintenance planning. The seven-step process we've outlined gives you a systematic approach to identifying potential issues before they compromise your system reliability or safety. Regular professional inspections, combined with ongoing preventive boiler maintenance, help facilities maintain consistent heating and hot water services that support patient care, therapy programs, and daily operations throughout changing seasons and varying demand cycles.

Don't wait for a breakdown to prioritize boiler safety. Contact our certified technicians today to schedule your comprehensive boiler inspection and keep your facility running smoothly.

Reference:

https://www.boiler-planning.com/en/efficiency/basics/combustion-efficiency.html