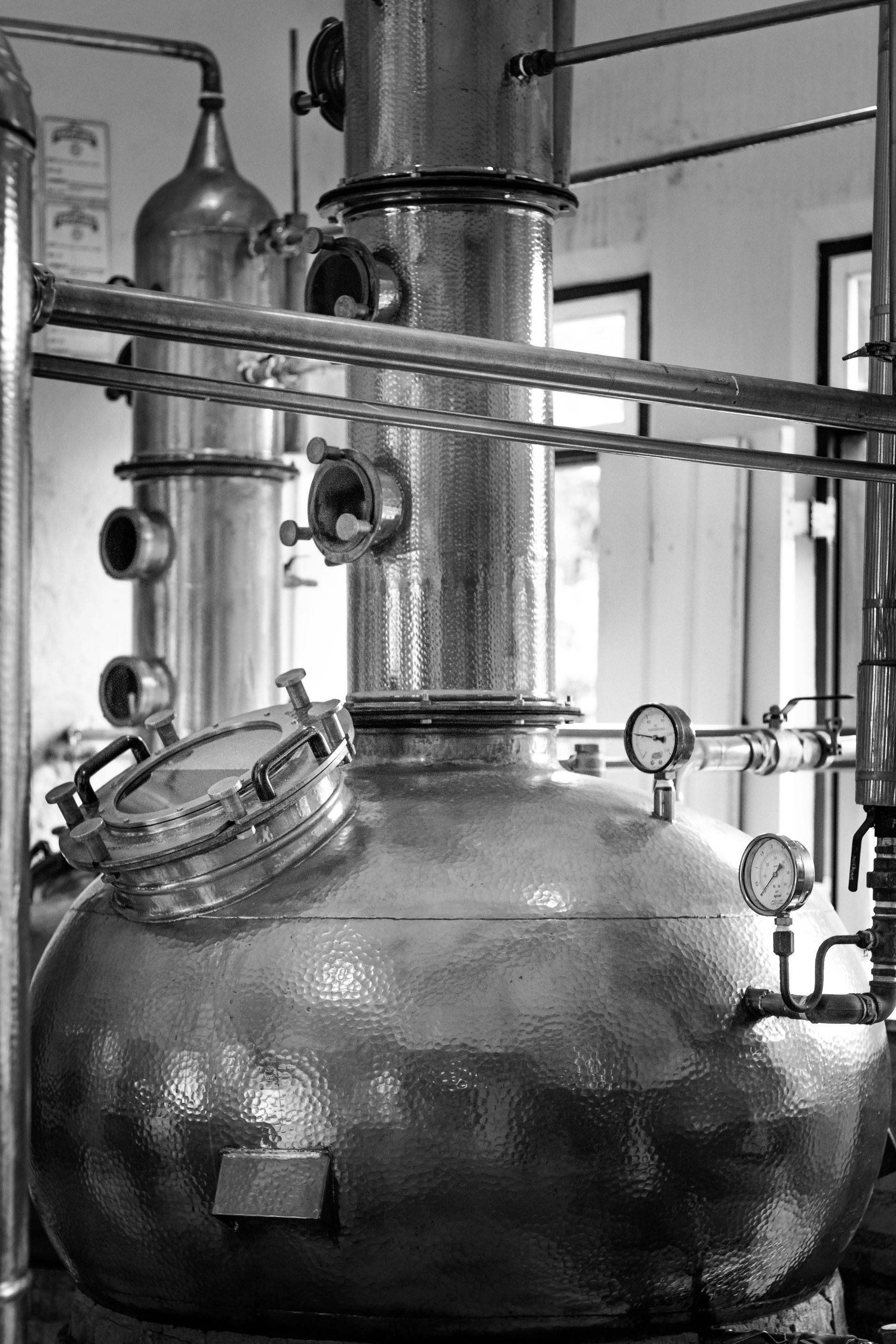

5 Proactive Boiler Maintenance Tasks to Prevent Downtime

Keeping your boiler running smoothly doesn't have to be a guessing game. When you stay on top of regular preventative maintenance, you can avoid those emergency calls at ungodly hours. A few simple preventive steps today can save you from costly repairs and unexpected downtime tomorrow. In addition to maintenance, knowing when to contact boiler service providers keeps your facility running uninterrupted all year round.

Key Takeaways

- Regular water quality testing prevents scale buildup and extends equipment lifespan

- Annual combustion analysis improves fuel efficiency and reduces operating costs

- Monthly safety valve inspections ensure proper pressure relief and prevent dangerous conditions

- Seasonal cleaning schedules maintain good heat transfer and prevent system failures

- Professional tune-ups identify potential issues before they cause expensive downtime

- Good maintenance logs track system performance and predict replacement needs

1. Essential Water Quality Management

Water quality is probably the most important factor affecting how long your boiler lasts and how well it performs. Poor water conditions cause scale buildup, corrosion, and premature component failure that can shut down operations without warning.

Testing Parameters and Frequency

Good water quality management means testing multiple parameters on a regular schedule. Commercial and industrial facilities should check pH levels, total dissolved solids, hardness, and alkalinity at least weekly. High-usage systems benefit from daily testing during peak seasons, especially in healthcare and rehabilitation facilities where consistent temperatures are important.

You'll want to test both incoming feedwater and boiler water samples. Incoming water quality affects what treatment chemicals you need, while boiler water conditions tell you how well your treatment program is working under real operating conditions.

Here are the important water parameters that need regular monitoring:

- Chloride levels - Speed up corrosion in stainless steel components, so you need strict limits based on your system materials

- Sulfate concentrations - Cause scaling that reduces heat transfer efficiency by up to 15% and increases fuel costs

- Silica content - Forms hard, glass-like deposits that resist chemical cleaning and require expensive mechanical removal

- Water conductivity - Gives you early warning of dissolved solids buildup and treatment system problems

- pH levels - Control corrosion rates and treatment chemical effectiveness throughout the system

Water conductivity measurements give you an early warning when dissolved solids start building up. Regular conductivity trending helps you spot gradual increases that point to treatment system problems or changes in your source water quality.

Treatment System Maintenance

Your water treatment systems need their own maintenance schedules to work properly. Good treatment system maintenance prevents boiler maintenance service calls and helps equipment last longer. Many modern facilities install monitoring systems that track treatment effectiveness and alert operators when problems develop.

Here are the treatment system components that need regular attention:

- Chemical feed pumps - Monthly calibration checks and component replacement before failure to maintain proper chemical dosing

- Filtration systems - Element changes based on actual usage rather than time intervals to keep filtration working well

- Softener regeneration - Cycles aligned with actual hardness levels for good efficiency and chemical usage

- Ion exchange resins - Regular inspection and capacity analysis for the right replacement timing to prevent breakthrough

- Storage tank maintenance - Regular cleaning and inspection to prevent contamination and ensure chemical integrity

Softener regeneration cycles should match your actual water hardness levels rather than preset schedules. Over-regeneration wastes chemicals and increases operating costs, while under-regeneration allows hardness breakthrough, which damages boiler components. Professional water treatment specialists can analyze your system performance and recommend the right regeneration timing for both protection and efficiency.

2. Professional Combustion System Analysis

Combustion efficiency directly affects your operating costs and environmental compliance. Annual professional analysis spots performance problems before they reach levels that trigger equipment shutdowns or regulatory violations. Industrial boiler maintenance programs often document efficiency improvements that pay for professional tune-up costs within the first heating season.

Efficiency Improvement Process

Professional boiler tune-ups include thorough combustion analysis using calibrated instruments. These adjustments typically improve efficiency by 2-5%, reducing fuel costs while helping equipment last longer through proper operating conditions. The analysis process involves adjusting air-to-fuel ratios, cleaning combustion chamber surfaces, and calibrating control systems.

Key combustion analysis measurements include:

- Oxygen levels - Determine the right air-fuel ratios for maximum efficiency and complete combustion

- Carbon monoxide content - Shows incomplete combustion that needs burner adjustment or maintenance

- Stack temperature - Reveals heat exchanger condition and fouling levels affecting efficiency

- Draft conditions - Ensure proper combustion air flow and safe venting of combustion products

- Excess air levels - Directly affect fuel consumption and operating costs through heat loss

Stack temperature trends give you valuable insight into heat exchanger condition and overall system performance. Rising stack temperatures often mean fouling on heat transfer surfaces that reduces efficiency and increases operating costs. Professional technicians evaluate environmental factors and recommend appropriate maintenance frequencies for the best performance.

Emission Compliance Verification

Environmental regulations require specific emission levels that well-maintained boilers easily achieve. However, degraded combustion conditions can push emissions above permitted levels, triggering compliance issues that force temporary shutdowns. Facilities must maintain documentation proving compliance to avoid regulatory penalties.

Annual testing verifies compliance with nitrogen oxide, sulfur dioxide, and particulate matter limits. Healthcare and rehabilitation facilities face particular scrutiny due to their sensitive populations, making consistent compliance important for maintaining operating permits. Early identification of emission trends allows corrective action before violations occur.

Modern monitoring equipment can provide continuous emission tracking that spots problems immediately rather than waiting for annual testing. These systems alert operators to developing issues that could lead to compliance violations, allowing corrective action before mandatory reporting becomes necessary.

3. Safety System Inspection Protocol

Safety devices protect both equipment and personnel from dangerous operating conditions. Monthly inspection of safety valves, pressure gauges, and control systems prevents serious failures that could endanger facility occupants.

Pressure Relief Valve Testing

Safety valves require functional testing rather than just visual inspection. Monthly testing involves manually lifting valves to verify free operation and proper sealing upon closure. Professional technicians use specialized tools to test valve operation without disrupting system operation.

Good safety valve maintenance includes:

- Mounting inspection - Check configurations and discharge piping for obstructions

- Pressure testing - Document opening pressure and reseating characteristics

- Spare valve maintenance - Keep replacement valves available for critical systems

Temperature and Pressure Monitoring

Accurate gauge readings help operators spot developing problems before they cause shutdowns. Digital gauges offer improved accuracy and can provide data logging capabilities that support trend analysis and predictive maintenance programs.

Advanced monitoring capabilities provide:

- Continuous data logging - Reveals operating trends you can't see with manual readings

- Alert systems - Send notifications for developing problems via email or text

- Backup monitoring

- Extra protection for critical healthcare and therapy facilities

| Safety Component | Inspection Frequency | Key Indicators |

|---|---|---|

| Safety Valves | Monthly | Free operation, proper seating |

| Pressure Gauges | Monthly | Accuracy within ±2% |

| Temperature Controls | Quarterly | Setpoint accuracy, response time |

| Low Water Cutoffs | Monthly | Proper operation, clean contacts |

| Fuel Shutoff Valves | Quarterly | Complete closure, leak-tight sealing |

4. Regular Cleaning and Maintenance Schedules

Regular cleaning keeps heat transfer efficiency high and prevents buildup that leads to hot spots and component failure. Seasonal cleaning schedules align maintenance activities with operational demands while keeping your system available when you need it most. Water-side cleaning typically happens annually, while fire-side cleaning frequency depends on fuel type and quality.

Heat Transfer Surface Maintenance

Tube cleaning removes deposits that insulate heat transfer surfaces and force the system to work harder to meet demand. Professional cleaning services ensure proper procedures that remove deposits without damaging tube surfaces. The cleaning process requires specialized equipment and safety procedures that go beyond most facility maintenance capabilities.

Effective cleaning procedures include:

- Chemical cleaning - Dissolves mineral deposits using controlled acid solutions with precise concentration and temperature

- Mechanical cleaning - Removes stubborn deposits through brushing or high-pressure water systems

- Inspection during cleaning - Reveals tube condition, thinning, stress cracking, and corrosion patterns

- Efficiency verification - Testing before and after service confirms cleaning effectiveness and heat transfer improvement

- Documentation - Maintain records of cleaning results to fine-tune schedules and identify problem systems

Heat exchanger inspection during cleaning reveals tube condition and spots potential problems before they cause failures. Early identification of tube problems allows planned replacement during scheduled maintenance rather than emergency repairs that disrupt facility operations.

Burner and Combustion Chamber Care

Burner maintenance includes cleaning fuel nozzles, adjusting electrode positions, and verifying ignition system operation. Professional burner service includes combustion analysis to fine-tune air-fuel ratios and minimize emissions while maximizing efficiency. Clean burners provide stable combustion that reduces maintenance needs for other system components.

Important burner maintenance tasks:

- Combustion chamber inspection - Spots refractory damage, cracking, and spalling requiring repair

- Control system calibration - Maintains proper operation and safety interlocks for reliable performance

- Safety shutoff testing - Verifies flame sensors and gas valve controls operate within specified parameters

- Fuel system maintenance - Includes filter changes, pressure testing, and leak detection procedures

Refractory materials experience thermal cycling that eventually causes cracking and spalling, requiring periodic replacement to maintain system efficiency and safety. Minor refractory repairs during scheduled maintenance prevent major rebuilds that require extended downtime during critical heating periods.

5. Preventive Maintenance Documentation

Good maintenance records provide the foundation for effective preventive programs. Proper documentation tracks system performance trends, spots recurring problems, and supports warranty claims when component failures occur. Computerized maintenance management systems organize information for easy retrieval and analysis.

Performance Trend Analysis

Regular data collection reveals gradual changes that point to developing problems. Fuel consumption trends, operating temperature patterns, and maintenance frequency data help predict when major components need replacement. This information helps facilities schedule major maintenance during planned outages rather than responding to emergency failures.

Key performance indicators to track include:

- Fuel consumption patterns - Increasing consumption shows efficiency degradation requiring attention

- Operating temperature trends - Changes suggest heat transfer problems or control system issues

- Cycling frequency - Excessive cycling points to sizing, control, or maintenance problems

- Water quality results - Trending shows treatment system effectiveness and needed adjustments

Trending analysis helps facilities schedule major maintenance during planned outages rather than responding to emergency failures. This proactive approach reduces costs while minimizing disruption to facility operations, which is particularly important for healthcare and rehabilitation facilities.

Maintenance History Tracking

Detailed records of all maintenance activities support troubleshooting efforts and warranty claims. Records should include specific work performed, parts replaced, and performance measurements before and after service. Professional service providers often include thorough documentation as part of their preventive boiler maintenance programs.

Computerized maintenance management systems organize information for easy retrieval and analysis. These systems can generate maintenance schedules based on actual equipment usage rather than generic manufacturer recommendations, which helps both system reliability and maintenance costs.

Professional Boiler Maintenance Services

While facility staff can handle basic maintenance tasks, complex procedures require specialized knowledge and equipment. Professional boiler maintenance services provide expertise that ensures proper procedures and spots problems that untrained personnel might miss.

Industrial and Commercial Expertise

Professional boiler services understand the unique requirements of different facility types and operating conditions. Commercial boiler maintenance differs significantly from industrial applications due to load patterns, water quality, and regulatory requirements.

Specialized facilities like healthcare institutions benefit from maintenance providers who understand critical system requirements and regulatory compliance needs. These providers can schedule maintenance to minimize disruption while ensuring system reliability. Rehabilitation centers and therapy facilities require consistent environmental conditions that make reliable boiler operation important for patient comfort and treatment effectiveness.

Professional maintenance advantages include:

- Performance guarantees - Contractors provide accountability for service quality and efficiency levels

- Operator training - Personnel education in basic maintenance and system monitoring

- Compliance documentation - Required records for regulatory and insurance requirements

Emergency Response Capabilities

Established maintenance relationships provide priority access to emergency repair services when unexpected problems occur. Regular service providers understand system configurations and maintain parts inventory that speeds repair completion.

Preventive boiler maintenance contracts often include emergency response provisions that guarantee specified response times during critical situations. These arrangements provide peace of mind while controlling maintenance costs through predictable annual budgets.

Frequently Asked Questions

How often should commercial boilers receive professional maintenance?

Most commercial boilers benefit from annual thorough maintenance with monthly monitoring visits. High-usage systems may require more frequent attention based on operating hours and water quality conditions.

What are the signs that boiler maintenance is overdue?

Increasing fuel consumption, frequent cycling, unusual noises, and water quality problems show maintenance needs. Early attention to these signs prevents more serious problems that cause unexpected shutdowns.

Can facility staff perform basic boiler maintenance tasks?

Basic tasks like water testing, visual inspections, and simple cleaning can be performed by trained facility staff. Complex procedures requiring specialized tools or safety considerations should be left to professional technicians.

How much downtime is required for annual boiler maintenance?

Typical annual maintenance requires 8-24 hours, depending on system size and scope of work needed. Proper planning can often schedule maintenance during periods of reduced demand to minimize operational impact.

What documentation should facilities maintain for boiler systems?

Important records include daily operating logs, water test results, maintenance work orders, and equipment manuals. Good documentation supports troubleshooting efforts and demonstrates regulatory compliance when required.

Final Thoughts

Effective boiler maintenance requires a systematic approach that combines regular monitoring, preventive care, and professional expertise to ensure reliable operation. Facilities that put good maintenance programs in place experience fewer emergency breakdowns, lower operating costs, and longer equipment life that maximizes their infrastructure investment while maintaining the consistent environmental conditions needed for great facility operations.

Don't wait for unexpected breakdowns to disrupt your facility operations. Contact our experienced boiler maintenance specialists today to schedule your preventive maintenance program and ensure reliable, efficient heating all year long.

Reference:

https://cleaverbrooks.com/Product/water-softeners